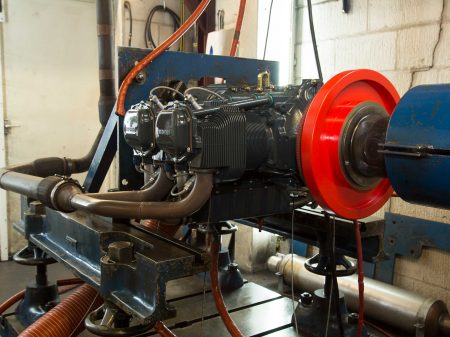

Norvic has continuity of highly-trained engineers with over 150 years’ collective experience in Continental & Lycoming engine overhaul and repair, working to Norvic’s clear procedures and quality control in our modern engine shop in Cambridgeshire.

A Norvic Overhaul or a Norvic Exchange Overhaul engine is of the exact same standard as an OEM Rebuilt engine, not their Overhauled engine. Compare our prices with the OEM Rebuilt.

You’ll find we deliver unparalleled customer service—doing exactly what we promised, and making every effort to meet your special requirements. Turn to us for all your needs in GA (General Aviation) light aircraft engine overhaul, repair and sudden engine stoppage (propeller/rotor strike Shock) including:

- Lycoming engine overhaul / exchange

- TCM Teledyne Continental engine overhaul / exchange

- Franklin engine overhaul / exchange

At our advanced engine shop, all of the technical work is carried out by Part 145 Certified personnel in accordance with the companies below approvals.

UK PART 145 APP REF: UK.145.01182

EASA PART 145 APP REF: EASA.145.3169

FAA APP REF: 33NY343C

Jordanian CARC APP REF: CARC.F.AMO.28

Philippine CAAP AAP REF: 412-F

Indonesian DGCA AAP REF: 145F-987